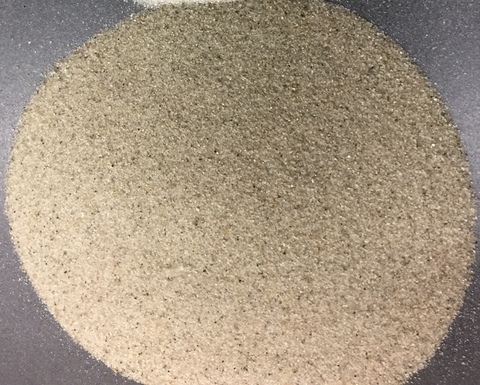

Silica Sand

About Silica Sand

it’s composed essentially of quartz grains are used in the industry as silica sand. Silica sands are of marine, fluvial (river) or eolian (wind) origin. The most sought-after deposits have high silica contents and well graded quartz grains (rounded to subrounded).

The hardness of quartz makes it more resistant to abrasion than other minerals in a rock. When rock formations are subjected to erosion by water, wind or frost action, quartz will successfully resist destruction. It accumulates along seashores to form sand beaches or in the meanders of rivers. After becoming compressed and naturally cemented, these sands form sandstones, quartz sandstones or orthoquartzites.

Natural sand, once sorted, is a highly sought-after abrasive material. Sand can also be produced by grinding and sieving sandstones and quartzites. Sieved sand is the material of choice for filtering drinking water and for purifying wastewater.

Sands with high uniformity coefficients are good choices for hydraulic fracturing. They are used during drilling to increase rock permeability and facilitate the withdrawal of petroleum or natural gas trapped in sedimentary rocks (shale).

Silica Sand Uses

Ceramics & Refractories

Ground silica is an essential component of the glaze and body formulations of all types of ceramic products, including tableware, sanitary ware and floor and wall tile.

Filtration and Water Production

Industrial sand is used in the filtration of drinking water, the processing of wastewater and the production of water from wells.

Paint and Coatings

Paint formulators select micron-sized industrial sands to improve the appearance and durability of architectural and industrial paint and coatings.

Glassmaking

silica sand is the primary component of all types of standard and specially glass. It provides the essential SiO2 component of glass formulation and its chemical purity is the primary determinant of color, clarity and strength.

Metal Casting

Industrial sand is an essential part of the ferrous and non-ferrous foundry industry. Metal parts ranging from engine blocks to sink faucets are cast in a sand and clay mold to produce the external shape, and a resin bonded core that creates the desired internal shape.

Metallurgical

Industrial sand plays a critical role in the production of a wide variety of ferrous and non-ferrous metals. In metal production, silica sand operates as a flux to lower the melting point and viscosity of the slags to make them more reactive and efficient.

Chemical Production

Silicon-based chemicals are the foundation of thousands of everyday applications ranging from food processing to soap and dye production. In this case, SiO2 is reduced to silicon metal by coke in an arc furnace, to produce the Si precursor of other chemical processes.

Oil and Gas Recovery

Known commonly as proppants, or "frac sand,” industrial sand is pumped down holes in deep well applications to prop open rock fissures and increase the flow rate of natural gas or oil.

Recreational

Industrial sand even finds its way into sports and recreation. Silica sand is used for golf course bunkers and greens as well as the construction of natural or synthetic athletic fields.

Building Products

Industrial sand is the primary structural component in a wide variety of building and construction products. Whole grain silica is put to use in flooring compounds, mortars, specialty cements, stucco, roofing shingles, skid resistant surfaces and asphalt mixtures to provide packing density and flexural strength without adversely affecting the chemical properties of the binding system.

Locations in Egypt

Zafarana Ras Ghareb, Red Sea

Red Sea coast

Abu Zenimah city on the northern bank of the Gulf of Suez.

See how we're transforming the industry. Get involved today!

Unlock the potential beneath the surface. Partner with us for your next mining project. Contact us today!